|

PE-AL aluminum plastic composite board production line

|

|

|

1. PE-AL aluminum plastic composite board production line introduction

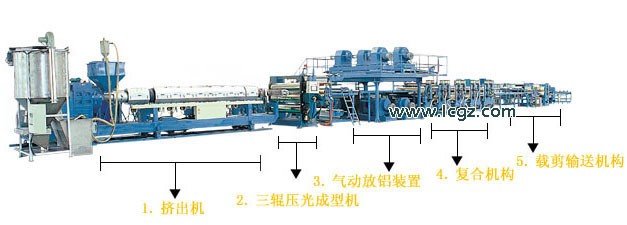

Aluminum plastic composite Panel (ACP) is a new type of construction and decoration materials, which has low density, high strength, standard colors and easy installation features. Composite Panel Production Line is a professional on-line continuous production of APCP equipment, aluminum composite panel production line (equipment) is the introduction of foreign advanced technology, based on production practice by professional engineers conducted several process technology improvements, the equipment to keep improving the technology level in the international technical level with the leader in high efficiency, easy operation and other characteristics. Is used, the inter wall and outer wall decoration PE aluminum composite panel production line, products effective width 1220 ~ 2050mm, thickness 1.0 ~ 5mm, in which the thickness of aluminum foil 0.026 ~ 0.5mm, using a specially designed screw structure to meet the 100% recycled materials back to the production , extruder output compared with other similar has been greatly improved. And the introduction of new technology, will be the most critical technical indicators APCP - peel strength increased to a very good state, so that flatness of aluminum-plastic board, weather sexual performance are increased accordingly. Equipment sold domestically and exported to Indonesia, Russia, Vietnam, India and other countries. 2. PE-AL aluminum plastic composite board production line technical parameters

3. PE-AL aluminum plastic composite board production line picture

|

|