|

PE,PP Single wall corrugated pipe production line

|

|

|

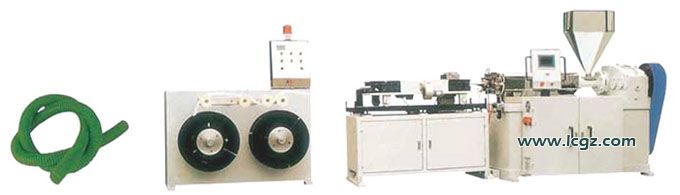

1. PE,PP Single wall corrugated pipe production line introduction

The machine main produce PVC, PP, PE, PA as raw materials small diameter single wall corrugated pipe. Through the corresponding mould forming both inside and outside a smooth, corrugated uniform the corrugated pipe Product. Corrugated pipe production line configuration single screw extruder or twin-screw extruder, corrugated pipe forming machine, extrusion die, corrugated mould block, air-cooled or water cooled device, counter, automatic double-disc coiler, can continuously extrusion forming a variety of specifications for the size of diameter the single wall corrugated pipe. Special screw, mould design and reasonable structure, convenient and reliable replacement of mold solved easily screw barrel wear and material forming difficult problem, the production line speed, stable operation, simple easy-to-use control. The equipment to produce single wall corrugated pipe high temperature resistance, corrosion resistance, wear-resistant, high strength. Threading pipe for electrical, automotive threading tubes, sheath tubes, machine tools, packaging, food machinery, electric locomotive, engineering, installation, lighting, automation instrumentation and other areas the market demand. 2. PE,PP Single wall corrugated pipe production line technical parameters

3.PE,PP Single wall corrugated pipe production line picture

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||